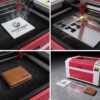

Laser Engraving and Cutting Machine (80 Watt)

₹184,999.00 Excl. GST

₹218,298.82 Incl. GST

Shipping Extra

The Laser Engraving and Cutting Machine (80 Watt) is a professional CO2 laser system capable of engraving and cutting wood, acrylic, leather, ceramic, MDF, rubber, fabric, glass, and over 1,000 other non-metallic materials with razor-sharp precision. Powered by an 80W water-cooled CO2 laser tube with a 500×700 mm working bed, it achieves engraving speeds up to 500mm/s, cuts materials up to 15mm thick in a single pass, and supports LightBurn, CorelDRAW, and AutoCAD via USB, Ethernet, and Wi-Fi. For metal marking applications, pair it with our Fibre Marking Machine for a complete engraving workshop setup. Weighing 148 kg and measuring 114 × 76 × 69 cm, available as a single unit.

The Laser Engraving and Cutting Machine (80 Watt) is a full-size industrial CO2 laser system engineered for businesses and workshops that demand precise, high-speed engraving and cutting across a wide range of non-metallic materials. The 80W water-cooled CO2 glass laser tube operates at a 10.6µm wavelength, delivering sufficient power to cut materials up to 15mm thick in a single pass and engrave at speeds of up to 500mm/s with a minimum character size of 0.1mm — producing clean, detailed results on wood, MDF, acrylic, leather, glass, marble, stone, ceramic, rubber, fabric, cardboard, cork, EVA foam, and over 1,000 other compatible materials. The spacious 500×700 mm (20×28 inch) working bed provides ample workspace for large-format projects, and front and rear pass-through doors allow oversized sheets and rolls to feed freely through the machine without size restrictions.

Control is handled by an upgraded Ruida DSP digital controller with a full-colour LCD display that monitors laser power, speed, and processing status in real time. It supports raster engraving, vector cutting, and combined operating modes, and includes a power-off resume function that restarts interrupted jobs from the exact stopping point — protecting both materials and production time. File transfer is supported via USB flash drive, USB cable, Ethernet, and Wi-Fi, and the machine is fully compatible with LightBurn, CorelDRAW, AutoCAD, and RDWorks V8 on Windows, macOS, and Linux. The built-in air assist system directs a pressurised airstream through the laser head nozzle during cutting, displacing smoke, debris, and combustible gases from the cutting path — resulting in cleaner cuts, finer engraving detail, and significantly reduced charring on the material surface. A water flow sensor monitors coolant circulation continuously and automatically prevents the laser from firing if water stops flowing — protecting the laser tube from heat damage during operation.

The work bed features dual interchangeable surfaces — a honeycomb platform for smaller and flat materials, and an aluminium knife-blade bed for larger, harder substrates such as thick acrylic blocks and MDF sheets. The height-adjustable lift table accommodates materials of varying thicknesses within a 230mm vertical range, and the red-dot laser pointer on the intelligent laser head precisely marks the engraving position and frames the project boundary before firing — eliminating positioning errors and material waste. The machine is well-suited to producing engraved Sublimation Tiles and personalised decorative items, or for precision-cutting Sublimation Glossy Metal Sheets into custom shapes for awards, signage, and branded merchandise. For businesses working across print and cut workflows, it pairs naturally with the Skycut C24 Cutting Plotter for vinyl, HTV, and sticker cutting applications — and with Both Side A4 Sublimation Paper for producing sublimated designs that can be laser-cut into custom shapes with perfect precision.

Safety features include an emergency stop button, key-lock power switch, automatic laser cut-off when the protective cover is opened, a tinted transparent viewing window for eye-safe process monitoring, and a built-in ventilation exhaust port for fume extraction. The machine is mounted on lockable caster wheels for easy repositioning across a production floor. It ships with a 12-month warranty on the machine body and laser tube, and carries CE certification for international compliance.

Weighing 148 kg and measuring 114 × 76 × 69 cm, with a total carton CBM of 0.598 m³ and a volumetric weight of 119.5 kg. Available as a single unit.

| Weight | 148 kg |

|---|---|

| Dimensions | 114 × 76 × 69 cm |