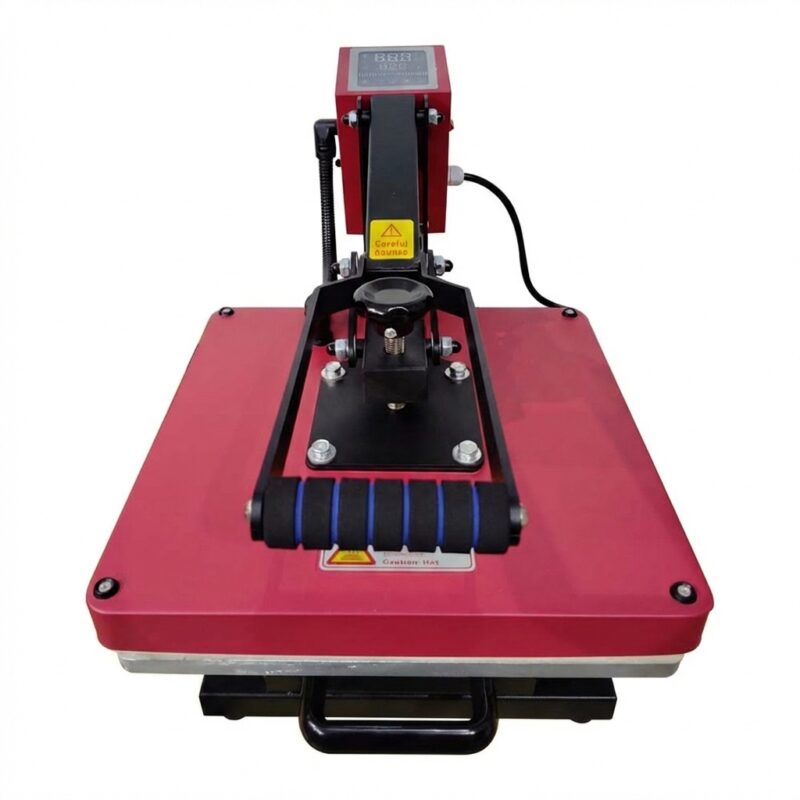

16×24 Double Bed Automatic Machine

₹105,000.00 Excl. GST

₹123,900.00 Incl. GST

Shipping Extra

The 16×24 Double Bed Automatic Machine is a heavy-duty power player designed for high-volume garment decoration and professional customization. Featuring an expansive heat platen and an innovative double-bed sliding system, it allows you to prep one garment while another is pressing, doubling your efficiency. With its “Auto Open” functionality, you can focus on your workflow without worrying about over-pressing or scorching your high-value transfers.

In a competitive customization market, speed and consistency are the two most important factors for success. The 16×24 Double Bed Auto Open Heat Press Machine is engineered specifically for businesses that have outgrown manual single-bed presses and need an industrial-grade solution to scale their production. This machine bridges the gap between hobbyist tools and high-end factory equipment, providing a professional edge to every print.

Double the Beds, Double the Output The standout feature of this model is its dual-bed configuration. By utilizing two lower platens, the machine eliminates the “idle time” found in traditional setups. While the heat platen is engaged on one side, the operator can safely unload and prepare the next garment on the second bed. This seamless “shuttle” workflow can effectively double your hourly output, making it the perfect choice for large orders of DTF transfers, sublimation, or screen-printed patches.

Automatic Precision and Safety Equipped with an advanced Auto Open mechanism, this machine removes the guesswork from the pressing process. Once the digital timer reaches zero, the heat platen releases automatically. This feature is a game-changer for busy shop owners, as it prevents accidental scorching and allows the operator to multitask across the room without needing to manually lift the press the second it finishes.

Expansive 16×24 Workspace The generous 16×24-inch heat platen provides ample surface area for oversized designs, jerseys, and hoodies that smaller presses simply cannot handle. The heating element is designed for edge-to-edge heat distribution, ensuring that pressure and temperature remain uniform across the entire substrate. Whether you are working with delicate vinyl or high-pressure DTF films, the adjustable pressure knobs and digital control center allow you to fine-tune settings for any material.

Built with a robust steel frame and an ergonomic layout, this machine is not just a tool—it is the central hub of a high-performance production environment.

| Weight | 32 kg |

|---|---|

| Dimensions | 180 × 60 × 40 cm |

| Capacity | 400 meter/hr |

| Maximum Cutting Speed | 100 mm/sec |

| Printing Speed | 20 sec |

| Automation Grade | Automatic |